Currently on the market eye wash products vary, prices vary, how do purchasers screen a good or bad eye wash?

The following editor will start from several aspects, to see a good eyewash should have what conditions.

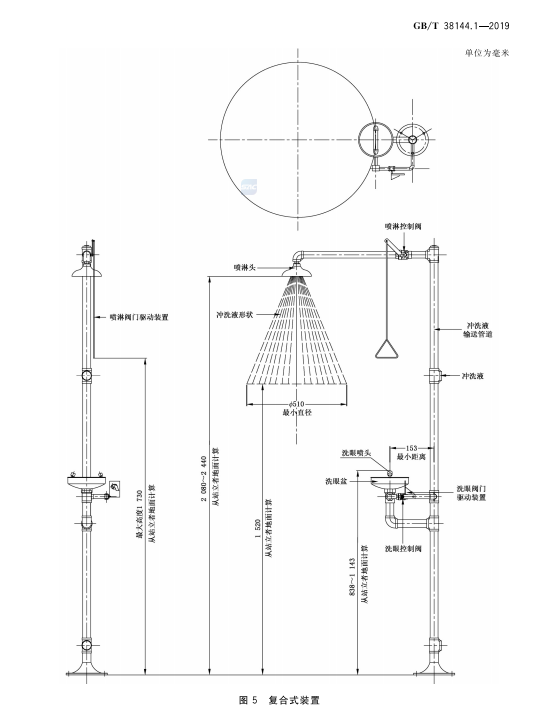

1. Eyewash implementation standards and design specifications

At present, our national standards and norms on the chemical industry involving the application of eyewash are.

Eye and face protection Emergency spraying and eyewash equipment" GB/T 38144-2019

Safety and Health Code for Chemical Enterprises HG 20571-2014 l

Design Hygiene Standards for Industrial Enterprises GB Z1-2010l

General Design of Accident Shower and Eyewash Scheduled Q / SH0700-2008l

Code of Occupational Safety and Health Design for Petrochemical Enterprises" SH3047-93l

Safety and Health Regulations for Chemical Powder Engineering" HG 20532-93

Personal Protection Emergency System Setting" HGT 20570.14-1995

The international standards for eyewash apparatus are

American Eyewash Standard ANSI/ISEA Z358.1-2014

Emergency Eyewash and Shower Standardl

European Eyewash Standard EN 15154:1/2-2006 and 15154:3/4-2009

Emergency Eyewash and Shower Standardl

Australian Standard AS 4775-2007

Emergency Eyewash and Shower Standard

For detailed standard requirements, you can search the above standard numbers of eyewash and shower by Baidu.

2. Size and flow rate standard of eyewash:

A good eyewash, size is necessary to meet the national standard for eyewash, online some of the second best most of them are very short and small.

3. the following do some good and bad comparison.

The height of good eyewash is generally around 2300㎜. The poor ones are generally 2000㎜.

The size of good eyewash basin will reach 300mm, while the poor ones are generally 250mm.

The good eyewash pipe will be made of pure 304 stainless steel, and the poor one is made of carbon steel.

The good eyewash will do appearance treatment as a whole, such as brushing, spraying, polishing and so on.

Poor eye washers are generally rough in appearance, do not do appearance treatment.

The installation connection of good eyewash is generally simple and easy for customers to install.

Poor eyewash installation are more complex, the customer is difficult to organize successfully.

Good eye washers have a strong pressure-bearing capacity, sealed tightly, and can generally withstand a maximum pressure of 1.6 MPa.

Poor eyewash is difficult to withstand high pressure, will be prone to leakage phenomenon.

Good eyewash nozzle will be set up filtering system and flow restriction system, the flow of water uniform, the size of the human body in line with the workstation science, to avoid personnel flushing process injury eyes.

Poor eye washers are generally more powerful water, infinite flow and filtration system, easy to hurt the eyes.

Good eyewash spray flow is umbrella-shaped water, and each outlet hole flow evenly, more easy to flush.

Poor eyewash spray will show straight down type, spray area and water holes are not uniform.

返回目录

返回目录